Coconut shell introduction

Coconut shell introduction

Coconut shell is the endocarp of the coconut, which has 0.61% ash, 36.51% lignin, 53.06% cellulose, and 29.27% pentosan. Coconut shell is born in the tropical coast. It is brown, and very hard.

Coconut shell application

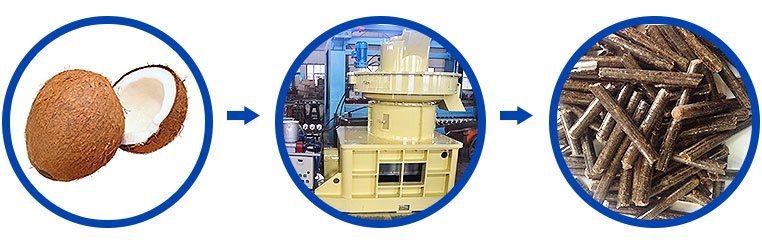

Coconut shell contains rich cellulose. As a new energy product in the world, it can be used as fuels after crushing, drying, pelletizing and packing.

Coconut shell pellet features

Coconut shell pellet features less ash, long burning time, large combustion heat and less pollution. Environmental protection is the most important feature.

Coconut shell pellet production line

Coconut shell pellet production line

1. Crushing process

Due to the quite hardness of the coconut shell, the coconut shell needs to be crushed from big chunk to small pieces by special coconut shell crusher.

2. Drying process

For containing certain moisture, crushed coconut shell enters drying machine through conveyor and feeding machine. The dryer can dry off the excess moisture to improve the pellet strength after pelletizing.

3. Second crushing process

After drying, the coconut shell pieces need to be crushed again into small fibrous pieces for better pelletizing.

4. Pelletizing process

After entering pellet mill through belt conveyor and feeding machine, the fibrous coconut shell pieces are pelletized into regular pellets by high strength extruding of the pellet mill.

5. Cooling and packing process

Pelletized particle has certain temperature, so it needs to be cooled by cooling machine after conveyed by belt conveyor. After cooling, the high quality biomass pellet is packed by the automatic packing machine.

All the above processes are equipped with dust collector, which makes the whole process no dust pollution.

Copyright © Zhengzhou Bobang Machinery Equipment Co.,Ltd

E-mail : fumill668@gmail.com

Tel:0086-371-86656959 86656957

Address: No.11 West Construction Road, Zhongyuan District,Zhengzhou City,Henan Province, China