About Peanut Shells

About Peanut Shells

Peanut shells are byproducts of peanut. The effective utilization rate of peanut shells is very low, because they are burnt directly or are used to feed animals generally. People of most areas in the world have realized to turn the peanut shells into treasures is necessary. Our company's peanut shell pellet machine can process them into particles used as a new kind of biomass energy. The application of peanut shell pellet machine offers a new way of realizing energy saving and environmental protection, and making profits for customers.

About Peanut Shell Pellet Mill

Peanut shell pellet machine is an amazing high efficiency equipment which can pelletize solid biomass wastes such as peanut shells, corn stalks, wheat straw, corn stover, corn cob, cotton stalks, soybean stem, weeds, twigs, leaves, sawdust and bark into particles with professional production technology. The finished pellet fuel is a new kind of bio-energy which can replace wood, coal, crude oil, liquefied natural gas. It is widely used in fields of heating, cooking, industrial boilers, chemical plants, biomass power plants etc.

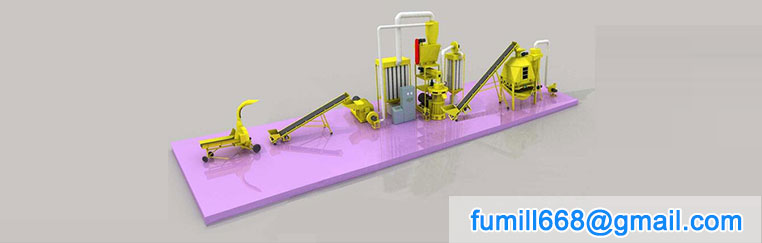

Peanut shells pelletizing process

Peanut shells pelletizing process

1. Crushing process

This process is to crush the peanut shells into fibrous pieces in order to be better pelletized.

2. Pelletizing process

This process is to grind the fibrous piece to pellet with 6mm,8mm,10mm and 12mm size, which is the core part of the whole production line. Before pelletizing, it needs to pick out iron, stone etc. our company adopts the most advanced vertical ring die pellet machine to pelletize, which features minimum energy consumption, minimum wearing, maximum stress and wide application. What's more, it has lowest sensitivity to different materials.

3. Cooling process

The discharged pellets have the temperature of 70-90 degree, which is unable to be packed. The cooling machine will make the temperature reduce to minis or plus 5 degree with room temperature. And then the cooled pellets are packed. This process uses counterflow cooling machine, which features good dust cleaning and short cooling time.

4. Screening process

During pelletizing, cooling and conveying process there will produce some powder for collision. So it needs to use vibrant screening machine to separate the unqualified pellets to achieve the requirement of the packing.

5. Packing process

The final pellets need to be packed, and then sold to customers. It usually uses bags and tons bags. This process packs according to customer's requirement. The packing machine is automatic, which features large capacity, less labor and less packing cost.

Copyright © Zhengzhou Bobang Machinery Equipment Co.,Ltd

E-mail : fumill668@gmail.com

Tel:0086-371-86656959 86656957

Address: No.11 West Construction Road, Zhongyuan District,Zhengzhou City,Henan Province, China